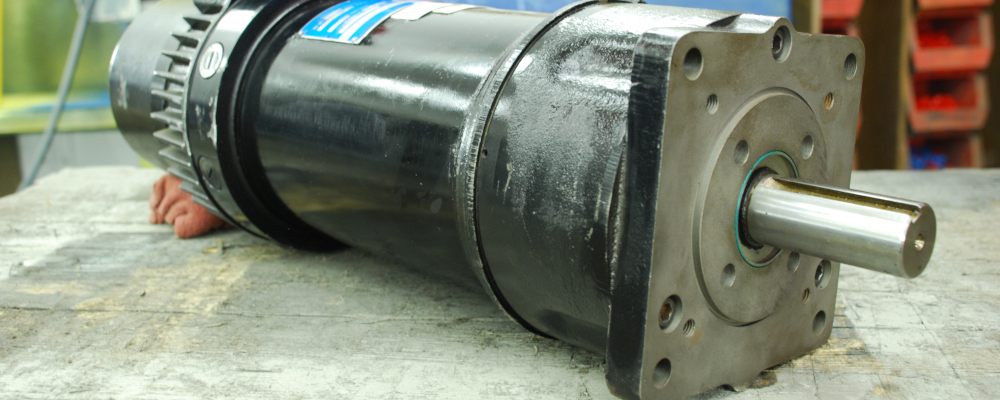

Servo motors are variable position electrical motors.

They control the action of the mechanical device in a servo mechanism and are vital to the proper operation of a wide array of industrial process equipment.

Industrial servo motors range in both size and type. For example, motors can be constructed for either AC or DC power sources, designed with a variety of base RPM and maximum RPM speeds. DC motors typically have tachometer feedback control, whereas AC motors will typically be coupled with an encoder, for precise control. They can be used to position ball screws, as well as a variety of geared devices.

Today, DC motors are still found in applications as small as toys and disk drives, or in large sizes, to operate steel rolling mills and paper machines. Modern DC motors are nearly always operated in conjunction with electronic devices. Two important performance parameters of DC motors are the motor constants: Kv and Km.

Brushed

The brushed DC electric motor generates torque directly from DC power supplied to the motor by using internal commutation, stationary magnets (permanent or electromagnets), and rotating electrical magnets.

Brushless

Brushless DC motors use a rotating permanent magnet or soft magnetic core in the rotor, and stationary electrical magnets on the motor housing. A motor controller converts DC to AC. This design is simpler than that of brushed motors because it eliminates the complication of transferring power from outside the motor to the spinning rotor. Some brushless motors are referred to as "synchronous motors," although they have no external power supply to be synchronized with, as would be the case with normal AC synchronous motors.

Repair Procedures:

- Hypot and Megohm test the windings for shorts to ground during run-in and run-out.

- Verify magnet strength and shorts between phases with back EMF testing.

- Recondition or rewind windings.

- Replace machine pilot, shaft and mounting area if needed.

- Replace any damaged connections.

- Verify encoder operation with custom software design to check optics, processor and communication signals.

- Run on a system drive and paint to specs.

Some of The DC Motor Brands We Repair:

- ABB

- Allen Bradley

- Baldor

- Bosch

- Cleveland Motor

- Danaher

- Fanuc

- Gould

- Indramat

- Nikki Denso

- Porter

- Powertrain

- SEM

- Siemens

- Yaskawa

- and many more

View Line Cards