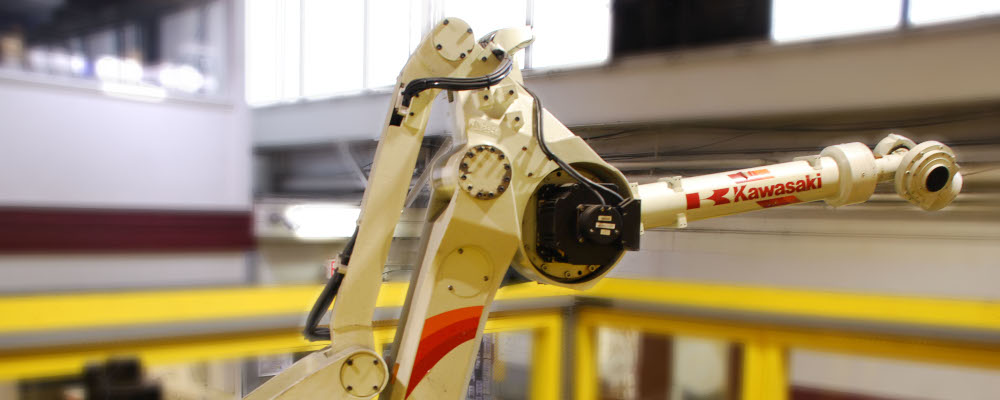

Kawasaki Robots are ideal for lifting payloads exceeding the limits of most industrial robots.

You can rely on them for handling engines, manipulating car bodies, transferring assemblies, moving large tools, lifting heavy construction equipment, manipulating appliances, handling large glass panels, fixtureless manufacturing, investment casting and forging – and a lot more.

You need on-demand reliable service and Kawasaki Robots deliver the goods. Even the best robots eventually need service. To maintain maximum uptime, you need more than a repair. Paragon Technologies goes beyond just replacing what needs to be fixed and returning your Kawasaki Robot. We remanufacture your robot, from motors to cables, wrists, drives, and even the nuts and bolts. When we’re done, we’ll provide you with an OEM quality remanufactured unit, with a rapid-fire turn-around time that gets you rolling quickly.

Give a Paragon Uptime Facilitator at the facility nearest you a call.

They can show you the enormous savings that can be realized when you remanufacture your Kawasaki Robot rather than replace it ahead of its time.

Repair Procedures:

- Purge and grease all gear boxes, RV Reducer cavities, and bushings.

- Motor brake test.

- Visually inspect for damaged connectors, replace when needed.

- Test all cables for wear and damage.

- Clean all cabinet heat exchange equipment including fans and filters.

- Check and replace seals as needed.

- Reset cabinets back to factory settings.

- Re-grease balancers and other bushing / bearings on the mechanical manipulator.

- Test and inspect teach pendants, replace overlays if needed.

- Test and inspect teach pendant cables.

- Repeatability test.

- 24 hour continuous operation test.

- Gear backlash adjustment if needed, test and inspect any belts or pulleys.

- Remove custom I/O and file comments.

- Change CPU battery and encoder batteries.

- Paint robot to OEM quality finish.

View Line Cards