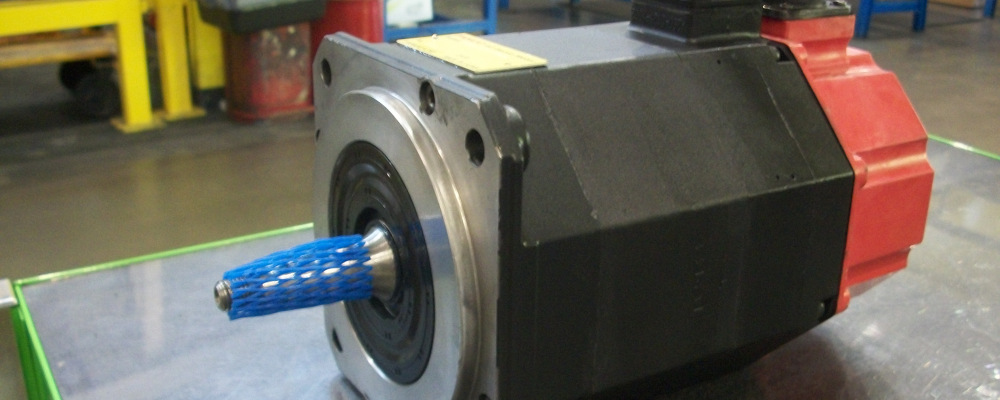

Industrial servo motors are available in a broad range of sizes and types.

These motors can be constructed for either AC or DC power sources, and they can be designed with a variety of base RPM and maximum RPM speeds.

DC motors typically have tachometer feedback control, whereas AC motors will typically be coupled with an encoder, for precise control. Industrial servo motors can be used to position ball screws, as well as to operate a broad variety of geared devices, including grinders and cutters of all sizes.

Paragon’s highly qualified, certified technicians can handle all your industrial servo repair needs.

We’ve invested millions in our facilities, including an amazing array of live bench-testing capabilities, to ensure your repair is done right and operating as it should when it meets full OEM specifications before we return it.

With our in-house repair and testing capabilities at our multiple locations, you’ll find having Paragon repair your existing servo motors is the cost-effective choice over replacement every time.

Repair Procedures:

- Hypot and Megohm test the windings for shorts to ground during run-in and run-out.

- Verify magnet strength and shorts between phases with back EMF testing.

- Recondition or rewind windings.

- Replace bearings and seals when needed.

- Replace machine pilot, shaft and mounting area, if needed.

- Replace any damaged connections.

- Verify encoder operation with custom software design to check optics, processor and communication signals.

- Run on a system drive and paint to specs.

Just Some Of The Many Brands We Repair:

- Fanuc

- Indramat

- Siemens

- Mitsubishi

- ABB

- Yaskawa

- Baldor

- Allen Bradley

- And Many More!

View Line Cards