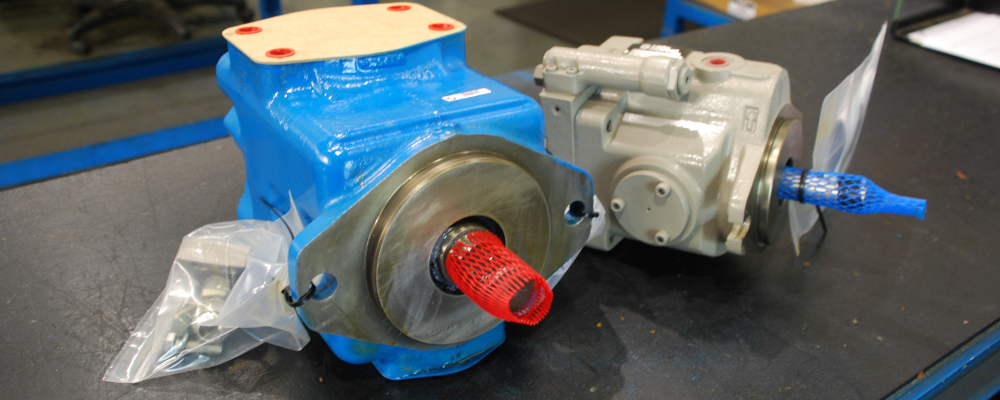

Not all vane pump repairs are created equal.

We consistently see vane pump failures returned from other repair companies due to inferior parts being used, as well as a lack of proper testing procedures.

Paragon repair technicians are certified and professionally trained to use only OEM specifications, or better. Our extreme stress testing of these units to 100% rated load and pressures fails all but the best performing pumps. Only then can a pump leave our facility as a Paragon Pump.

Repair Procedures:

- Each vane slot is inspected to ensure vanes will be stable and free moving in the slot.

- Every vane set is checked with a micrometer for proper thickness.

- Each set is refinished and inspected as a matched set. These tolerances are as tight as 0.0003 inches!

- Vane tip surfaces are restored to original condition in order to provide a proper vane tip-to-ring contact.

- Every cam ring inside contour is refinished using a series of polishing wheels that follow the contour to smooth out slight irregularities on the surface without changing the slope and dwell angles.

- The inside contour of the ring is brought to within 16 RMS finish.

- Every plate is precision lapped with a production machining line that uses different grits of lapping compound to remove imperfections. This process leaves every plate within 12 millionths of an inch of flatness.

- All depth of metering, timing notches and lubrication grooves are checked and recut to tolerance.

- Every plate is surface treated to allow the microscopic film of oil that must be present between the plate and the rotor.

- All units are 100% load tested on specific test stands up to 5000 PSI

Brands We Repair:

- Bosch

- Parker

- Nachi

- Denison

- Moog

- Racine

- Rexroth

- Vickers

View Line Cards