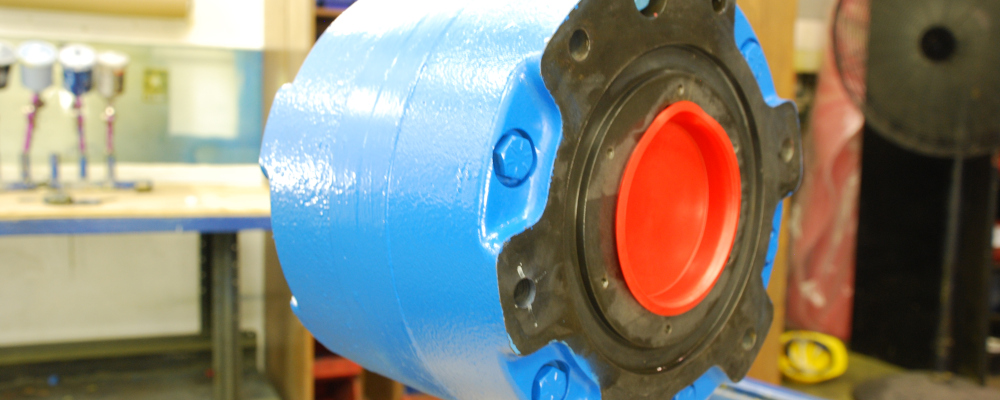

The Vickers & Tokimec MHT series motors have been around since the early 1970’s and are a time proven workhorse.

Even though many of these units have been obsolete for over 10 years, Paragon continues to repair these on almost a daily basis using only original OEM spare parts. Our load testing dynamometer is capable of 25,000 lb/ft which provides a 100% load test for all but a few larger size motors.

Paragon stocks many of the common sizes such as the MHT90, 150, 250, 500 and 750 so we are able to provide same day turn around or exchange on these units with just a phone call or email to our friendly customer service department.

Repair Procedures:

- Inspect rotor, vanes and guides for damage or wear & replace as necessary.

- Grind wear and pressure plates to OEM specification

- Replace all seals and o-rings with OEM equivalent or better materials.

- Hand polish vanes to within 0.0005 inches of each other

- Machine polish cam ring to ensure no burrs or pitting is present.

- Apply anti-wear coating to plates and cam ring

- Replace all springs with new units on every repair

- Toque units to proper OE specification

- Replace bearings

- Refurbish shafts when applicable.

Applications:

- Injection machine screw motors

- Continuous casting machines

- Straightener drives

- Wheel rim rolling machines

- Forging manipulators

- Winding machine drives

- Sheet line accumulator systems

- Pre-plasticizer drives

- Machine tool spindle drives

- Coil winders

- Conveyors

- Feeder screws

- Rolling mill screw down drives

- Drilling, boring machines

- Crushers

View Line Cards